我们的全套糖化系统采用国际标准 304 不锈钢制造,配备等离子切割、氩弧焊接及抛光工艺。

罐体内壁经过酸洗钝化,确保卫生安全;外表面镜面抛光,呈现高端工艺质感。

系统可提供四器、五器、六器配置,自由组合糖化锅、过滤槽、煮沸锅、漩涡沉淀槽,以满足不同规模和工艺的需求。

设备容量覆盖多种规模需求,系统具备高精度、高效率及高度自动化等特点,运行稳定可靠,适用于精酿啤酒及大型商业啤酒生产。

用于麦芽粉碎物与水的混合加热,实现淀粉高效转化,确保糖化过程稳定可控。

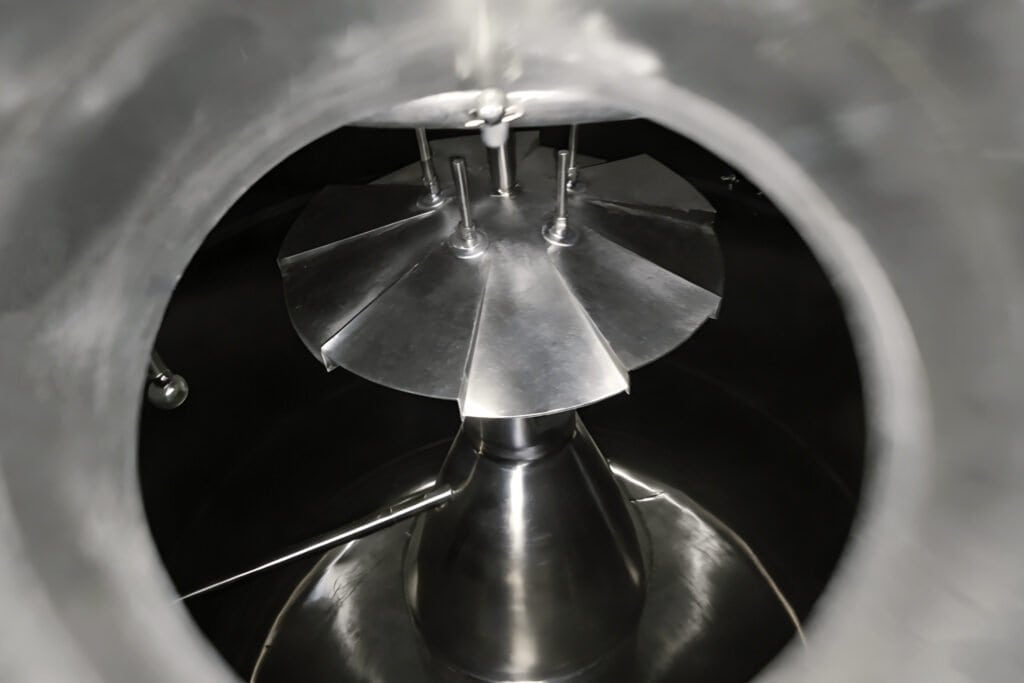

通过高效过滤与均匀布水,实现麦汁与糟渣的快速分离,保证出汁稳定与澄清度。

通过可控煮沸实现充分蒸发,稳定麦汁品质,并兼顾能效优化与热能回收。

用于煮沸后麦汁的澄清沉淀,有效去除热凝固物,提升后续发酵稳定性。

The mash tun is used for mixing milled malt with water under controlled heating. This process converts starches into fermentable sugars. Uniform temperature control ensures stable saccharification efficiency and consistent wort quality.

The lauter tun is equipped with a false bottom and adjustable rakes, driven by a frequency-controlled motor. This design enables efficient wort separation, prevents grain bed compaction, and improves extraction yield. Lautering efficiency is increased while reducing process time.

The boil kettle provides precise temperature control and uniform wort boiling. Its steam jacket and optimized internal circulation ensure thorough sterilization, stable wort quality, and high hop utilization. A dedicated exhaust system keeps the working environment safe and clean.

The whirlpool tun is used for wort clarification after boiling. The tangential inlet generates a strong vortex, forcing hot trub and solids to settle in the center while allowing clarified wort to be drawn off. This ensures clean wort ready for cooling and fermentation.

项目遍布全球,涵盖啤酒、饮料及乳品等领域,持续为客户提供高效、可靠的系统解决方案。

© 2012 – 2025 青岛贝斯特酿造工程技术有限公司 by • All Rights Reserved.