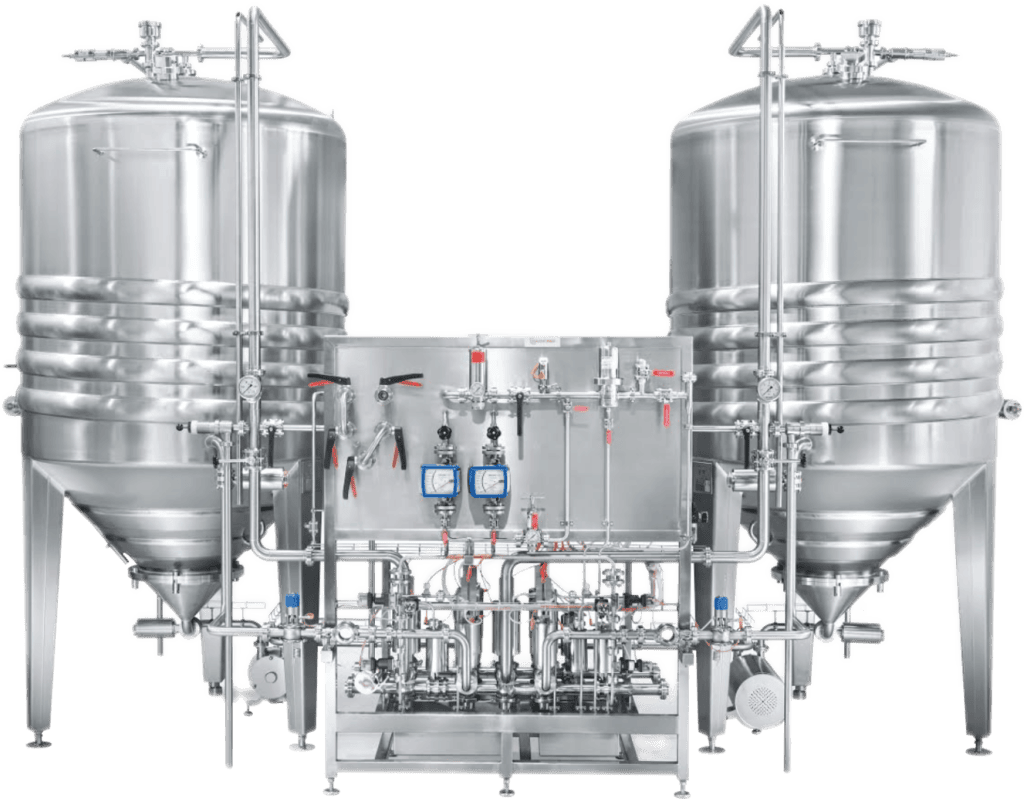

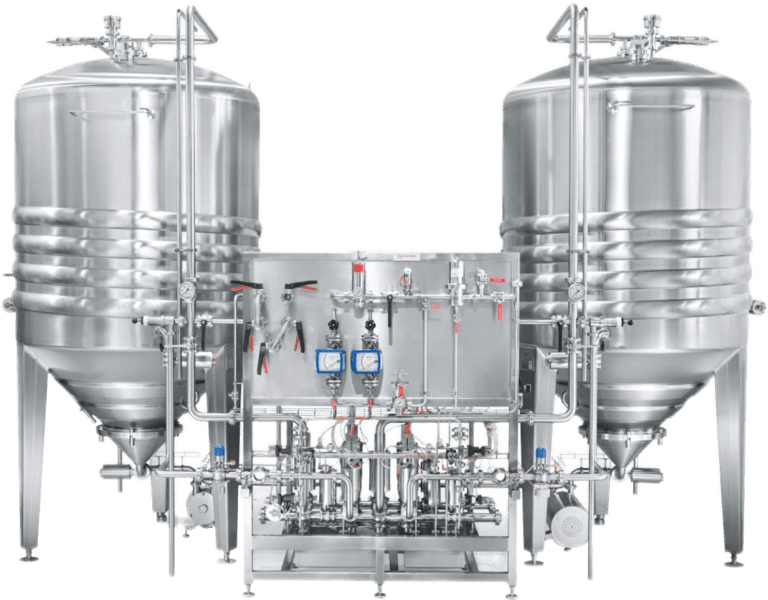

酵母扩培系统专为中大型啤酒厂设计,用于在严格无菌条件下培养和扩增纯种酵母。罐体、管路及阀门完成灭菌后,系统将麦汁和无菌压缩空气引入罐内,形成利于酵母生长的受控环境。

系统支持两级、三级或多级扩培工艺,单批处理能力覆盖 0.2HL–200HL,既适用于小规模扩培,也能满足大规模生产需求。稳定的工艺条件保证了酵母的高活力、高纯度和良好重复性,为后续发酵罐投酵提供可靠保障。

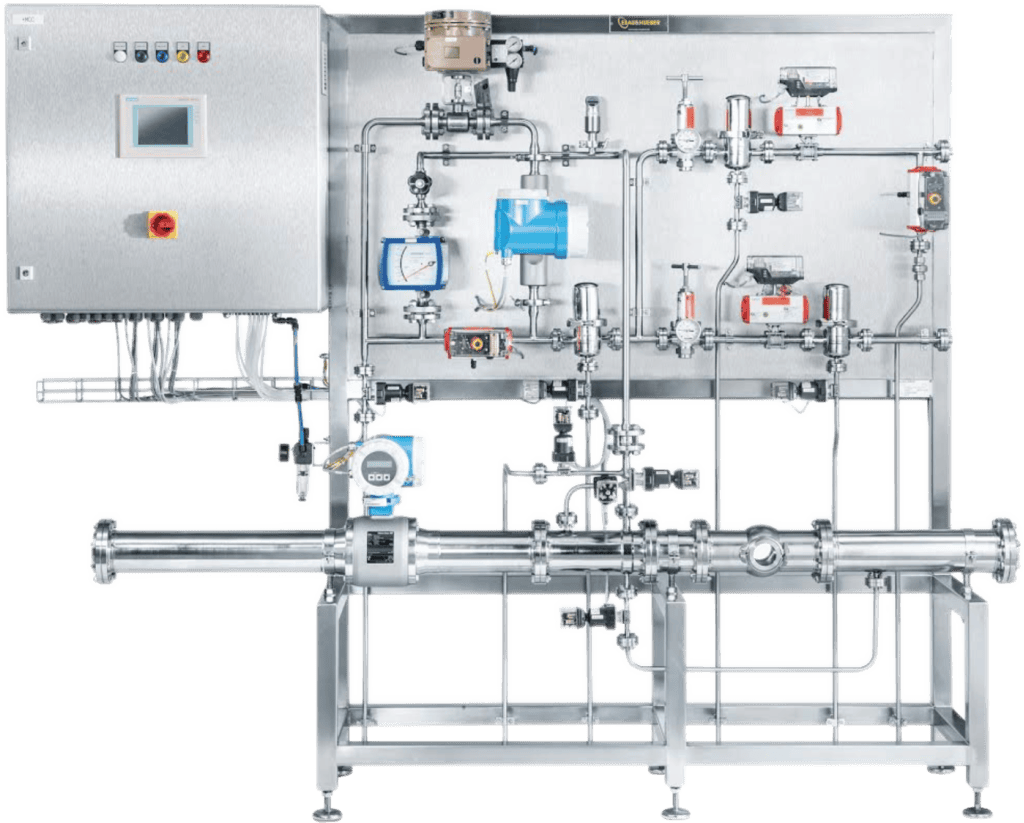

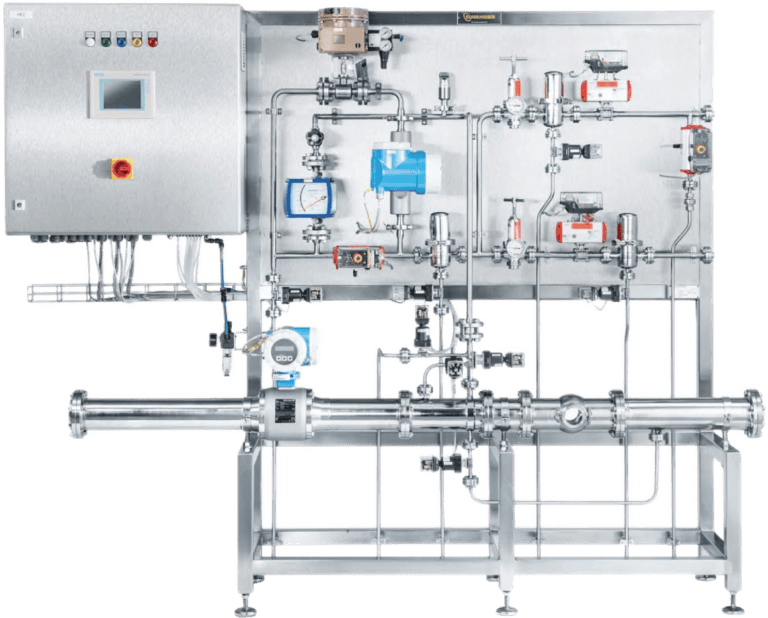

系统集成了先进的自动化控制,包括温度调节、曝气流量控制、压力管理以及灭菌程序等功能。

控制面板可实时监测溶解氧、压力和温度等关键参数,确保酵母扩培过程稳定可控、结果可重复。系统同时配置 CIP 就地清洗 和 蒸汽灭菌 功能,在整个工艺过程中保障高水平卫生与安全。

The system integrates advanced automatic control, including temperature regulation, aeration flow control, pressure management, and sterilization procedures.

A PLC-based control panel allows operators to monitor real-time parameters such as dissolved oxygen, pressure, and temperature, ensuring stable and reproducible yeast propagation. The system also includes CIP (clean-in-place) cleaning and steam sterilization functions, guaranteeing hygiene throughout the process.

酵母扩培罐采用高品质不锈钢制造,结构优化,适用于直接和间接冷却。模块化设计便于产能扩展,从 10L 实验室试验 到 100HL 及以上工业化生产,均可灵活配置。

根据客户工艺与厂房布局要求,系统可在自动化程度、罐型组合以及控制精度等方面进行定制,帮助不同规模的啤酒厂实现可靠、高效的酵母管理。

The yeast propagation tanks are manufactured from high-quality stainless steel with optimized structures for both direct and indirect cooling. The modular design allows flexibility in scaling capacity, typically ranging from 10L for laboratory trials to 100HL or more for industrial production.

According to customer requirements, the system can be tailored with different levels of automation, vessel configurations, and control precision, ensuring reliable yeast management for breweries of all sizes.

项目遍布全球,涵盖啤酒、饮料及乳品等领域,持续为客户提供高效、可靠的系统解决方案。

© 2012 – 2025 青岛贝斯特酿造工程技术有限公司 by • All Rights Reserved.